Background:

The industrial revolution was transition from induction motor to the new concept for constant and variable speed application to obtain maximum efficiency over a wide speed range (cost-efficient). All the industries needed more efficient method to attain different speed, this was until the development of PMDC motor. In PMDC motor, stator field is generated by permanent magnet and hence the field remains constant. Due to constant stator field, linear torque/speed characteristics can be obtained. By simply changing the applied voltage, motor speed can be changed and torque delivered is dependent on current. Since PMDC motor provides high torques, it is widely used in the application where accurate position control is required.

Introduction to BLDC:

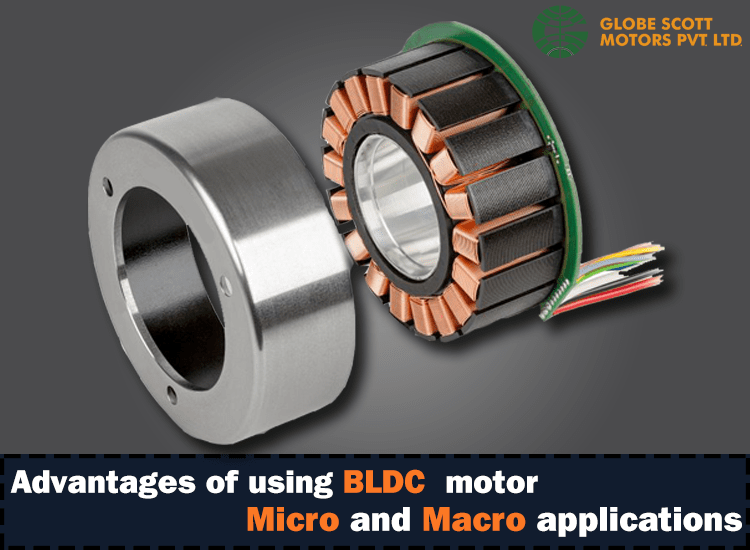

BLDC motor provides more advantages than induction motor (AC) and PMDC commutator motor (DC) alone. BLDC motor provides combine benefits of AC and DC motor along with its own unique advantages to application. It combines long life of induction motor and linearity of permanent magnet motor plus its adds own advantages like high speed operating range, high power to low weight ratio (i.e. compact design), improve torque density. Containing features of both AC and DC motors.

BLDC motor is similar to the synchronous motor; however, the construction varies in comparison. The design consists of housing, winding, permanent magnets and shaft. Core part of BLDC motor is the rotor. Rotor of BLDC motor uses magnet instead of coil winding. For speed control and smooth operation of motor hall sensor or rotor encoder along with controller are used for position sensing of rotor according to the sequential switching of switches are done. Like commutator and brushes in PMDC for mechanical commutation, BLDC uses electronic commutation.

BLDC motor can be operated by DC source directly using the that provide square wave phase current as excitation, which will produce the back EMF in a trapezoidal form. High speed BLAC motor is also well known as AC Servo motor. Sinusoidal current excitation is used for BLAC motor and back emf produced will be pure sinusoidal in nature. The performance of BLAC or Sine-wave excitation motor is almost similar to the would field induction motor rather than DC commutator motor.

Classification:

BLDC motor can be classified based on control strategy and rotor type.

1) According to control Strategy

i) Square wave excitation (BLDC motor)

ii) Sin-wave excitation (PMSM motor)

2) According to Rotor Type

i) Inner Rotor

- Surface Permanent Magnet Motor (SPM)

- Inset Permanent Magnet Motor

- Interior Permanent Magnet Motor (IPM)

ii) Outer Rotor.

Comparison of different motors:

| Sr. No | Parameter | DC(Universal) | Permanent Magnet DC Motor (PMDC) | AC Induction motor (IM) | BLDC or Permanent magnet Synchronous Machines (PMSM) |

|---|---|---|---|---|---|

| 1 | Voltage | AC,DC | DC | AC | AC, DC |

| 2 | Speed | 8000-20000+ | 350-6000 | 1200-3400 | 2300-3800 |

| 3 | Power | Very High | Medium | Low-Medium | High |

| 4 | Efficiency | 60-80 | 70-80 | 40-90 | 70-95 |

| 5 | Life | Low | Medium | Very High | Very High |

| 6 | Noise | Noisy | Medium | Quiet | Very Quiet |

| 7 | Speed Regulation | Poor | Fair | Good | Excellent |

| 8 | Starting Torque | High | Very High | Low-Medium | Very High |

| 9 | Reliability | Less | Medium | High | High |

| 10 | Controllability & Cost | Low | Low-Medium | Medium | Medium-High |

| 11 | Power Density | very low | Low | Medium | Very High |

Application:

- Medical – surgical robots, dialysis systems, pressure monitor, lab diagnostics,

- Electronics – feeders, wafer processing, camera crane, telescope control, optics, Nano-testing

- Robotics – humanoid robot, 6-legged robot, service, robotic vehicle, assembly, sewer robots

- Security – video surveillance, mobile inspection, cash dispensers, electromechanical locks

- Instrumentation – precision scales, deep sea sensors, laser leveling, seismometers, measurement